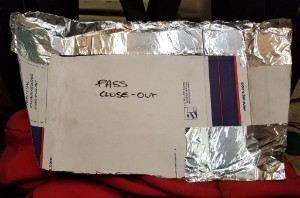

I've found that the aluminum tape you'd use for ductwork is really really good for patterns - it's stiff enough to hold a shape, soft enough to cut with a knife.

Off to harbor freight. Tools replaced.

| Patch panel created |

| Ugly welds applied. |  |

| From the inside. |

| Grind welds. |  |

| Grind, grind, grind. Still pending seam sealer. |

| Applied POR-15 to the inside of this area. I'm not going to be

cutting the contents out. This is the same can of POR-15 as shown in the 24 May 2003 update. The secret is to poke two holes in the lid and put screws in, rather than taking the lid off. It's getting low though. Need to get a new can. |  |

| Driver's side behind the door had some bubbling going on. This is less rust than I expected. |

Go back to the previous day (20 Feb 19)